Spartus ProMIG 335 DP- Dual Pulse Synergy is a multifunctional inverter welding device,

with which wire welding, electrode welding and TIG welding can be performed.

MIG/MAG welding modes: synergic with double pulse, synergic with pulse, synergic without pulse, with manual setting.

A machine suitable for use in industrial production with a high load capacity, with a load capacity of 300% at the maximum welding current of 60A.

With three-phase 400 V power supply.

Wire feed mechanism with four drive rollers.

A compact device with a built-in liquid cooling system, mounted on a base cart.

Modern technological solutions have been used in the design of the device.

Materials to be welded in the MIG/MAG mode: steel, stainless steel, acid-resistant steels and aluminum alloys.

Allows you to choose the type and diameter of the wire

Special emphasis has been placed on aluminum welding when creating programs and setting options.

Key Features:

1P Pulse- MIG/MAG welding with a pulse, which greatly simplifies spatter-free welding with a spray arc

2P Pulse (Dual Pulse) - MIG/MAG welding with a double pulse, especially suitable for aluminum welding, allows to achieve an approximate result that can be obtained with TIG welding

2T/4T welding modes

Spot welding with a timer

A simple and easy-to-set control panel enables precise control of all welding parameters.

In the manual mode, it is possible to adjust the arc voltage, the speed of the wire feed and the inductance for wire welding.

In the case of synergic control, the welding parameters are set according to the input data.

In the pulse mode, it is possible to set the pulse delta value, pulse frequency, pulse duration and base current.

The wire feed mechanism is equipped with four drive rollers, so a long welding torch can be used for welding.

A 5m torch is included in the set of the device. Despite the compactness and small dimensions, both 5 kg D200 and 15 kg D300 wire rolls can be used.

TIG welding can be performed with lift ignition and 2T/4T switching, current drop and aftergas duration can be set.

Arc force arc dynamics and Hot start e are helpful for MME welding with a melting electrode. simplified arc ignition.

Technical specifications:

Power supply 3 phases 400 V +-10% 50 Hz

Welding current 10- 300 A

Load capacity 60% 300 A

Welding arc voltage 14,5- 29 V

Wire feed mechanism with 4 drive rollers

Wire feed speed 2- 24 m/min

Wire diameter 0,8-1,2 mm

SPOT welding time timer

Wave control - inductance setting

Welding modes 2T/4T/s4T

Smooth wire acceleration when starting welding

Burn-back at the end of the welding arc

Pre- and post-gas

Spoolgun readiness

Welding current for TIG welding 10-300 A

Ignition of the arc during TIG welding with Lift

TIG current drop at the end of welding 0-10

Welding current when welding coated fusible electrodes 10-300 A

Arc force- adjusting the intensity of the welding arc MMA

Hot start - simplified arc ignition MMA

Current consumption MIG 14,8 A, MMA 16,3 A, TIG 11,5 A

Power factor cos phi 0,9

Insulation class H

Protection class IP21S

Weight 58,5 kg

Dimensions 930x490x930 mm

Complete set:

Welding device Spartus ProMIG 335 DP

Wire feed mechanism with 4 drive wheels

Water cooling system

Coolant Hypercoolant

Truck with 4 wheels

MIG torch Spartus SPP241 5m

Electrode holder with 3 m cable

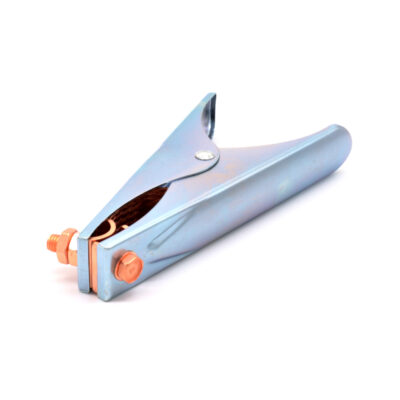

Earth terminal with 3 m cable

Gas hose between the machine and the cylinder