Inverter type wire welding device for both wire welding and electrode welding.

With three-phase power

Welding current in continuous operation mode at 60% load capacity: max. 300 A for wire welding and 250 A for electrode welding

The device is equipped with synergic control for MIG/MAG welding, allowing to set parameters manually.

Available synergistic programs for steel 0,8/1,0/1,2 mm wires.

A simple control panel allows you to adjust the following MIG/MAG parameters:

welding arc voltage, wire feed speed, 2T/4T mode, inductance, Arc Force (easier electrode melting in electrode welding), Hot Start (better electrode ignition) and VRD-reduced no-load voltage

Possibility to change the polarity - can also be used when welding with gasless filler wire.

The large digital screen allows you to monitor the exact parameters for example.

Wire feed mechanism with four drive rollers.

Technical specifications

Wire roll 300mm to 15kg

Power supply 3f 400V +-10%

Welding current for MIG welding 50-300A

Welding current for electrode welding 10-250 A

Welding current for TIG welding 10-300 A

Current consumption max MIG 17 A; TIG 14 A; MMA 13 A

Load capacity 60%- 300 A MIG and TIG; 60%- 250 A MMA

Arc voltage for MIG welding 16,5- 29 V

Wire feed speed 2- 12,5 m/min

Weldable wires 0,8-1,2 mm

Wire feed mechanism with four drive wheels

Power factor 0,93

Efficiency 85%

Protection class IP21S

Insulation class H

Dimensions 570x265x460 mm

Weight 19 kg

Included

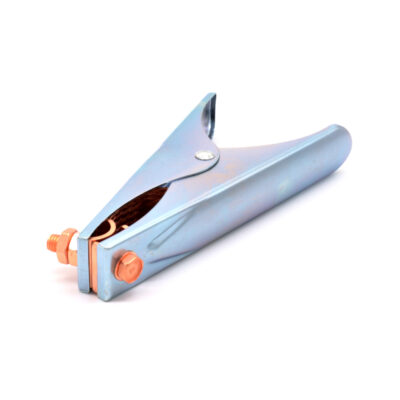

Ground terminal with 3m cable

Welding torch Spartus Easy 360 3m

Gas hose with hose clamps

Drive rollers for 0,8-1,0 mm wire.

Electrode holder with 3m cable.

MIG welding inverter EasyMIG315

€1,625.00

Description

MIG welding inverter EasyMIG315Inverter

Product description

MIG welding inverter EasyMIG315Inverter is a versatile wire welding device suitable for both wire welding and electrode welding. The device is three-phase powered and has a continuous duty welding current at 60% load. The maximum welding current for wire welding is 300 A and for electrode welding 250 A.

The device is equipped with synergic control for MIG/MAG welding, which also allows manual parameter setting. The selection includes synergistic programs for steel 0,8/1,0/1,2 mm wires. A simple control panel allows you to adjust many MIG/MAG parameters including arc voltage, wire feed speed, mode, inductance, Arc Force, Hot Start and VRD.

The device also has the ability to change the polarity, which allows it to be used when welding with gasless filler wire. The large digital display allows you to monitor the exact parameters. The device has a wire feed mechanism with four drive rollers.

Technical specifications

- Wire roll: 300mm to 15kg

- Power supply: 3-phase 400V -10%

- Welding current for MIG welding: 50-300A

- Welding current for electrode welding: 10-250A

- Welding